TN-3409E

The preferred equipment for milling the shape of cabinet door panels

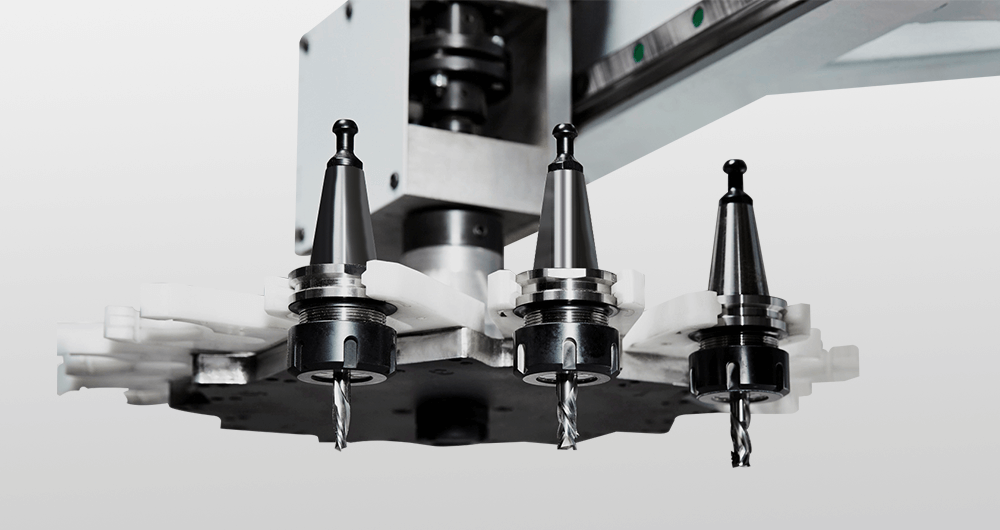

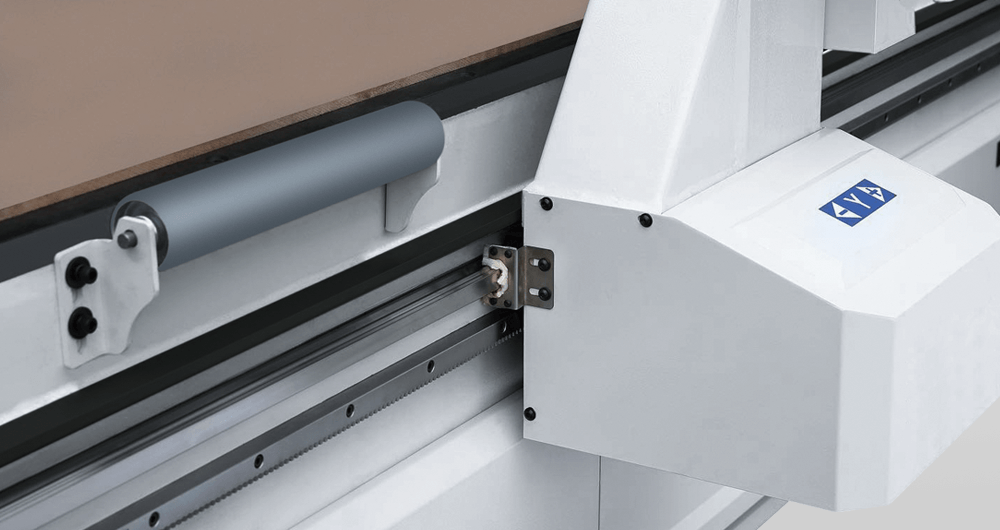

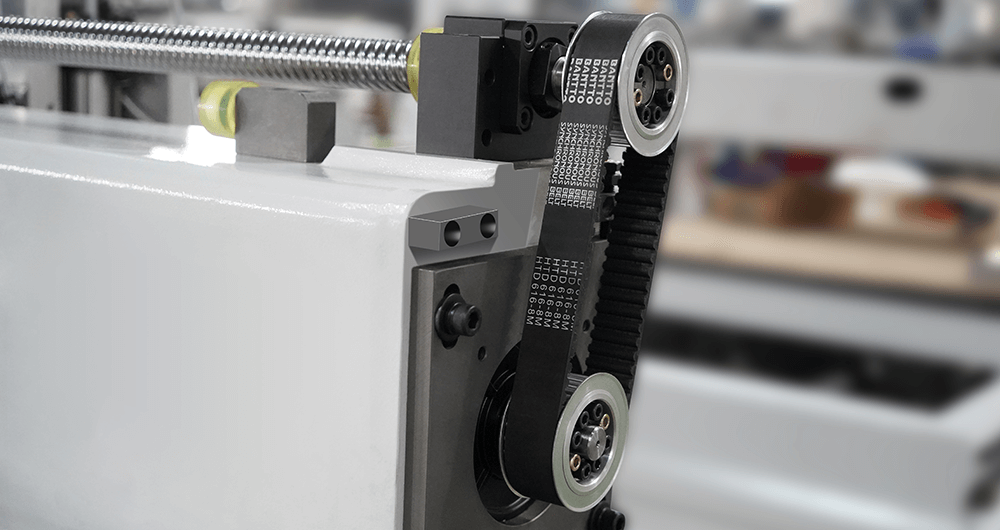

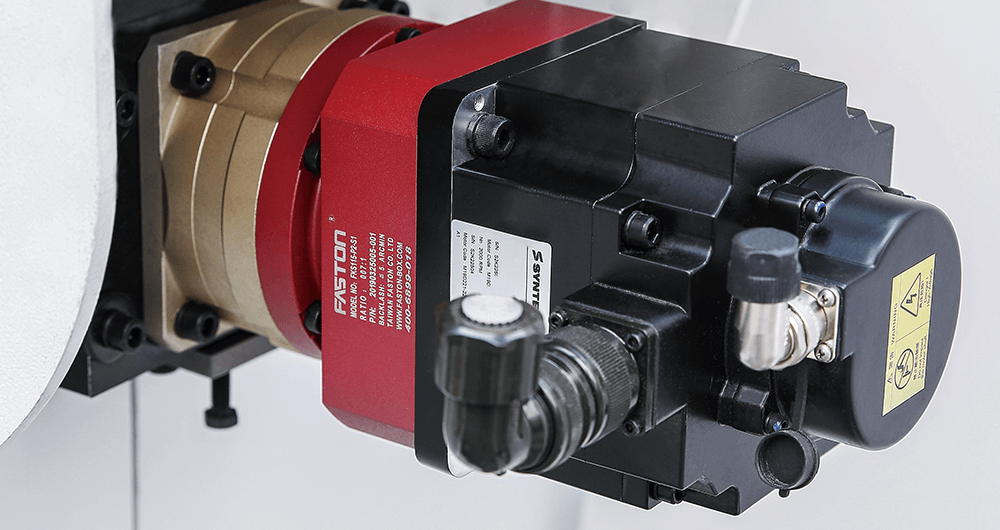

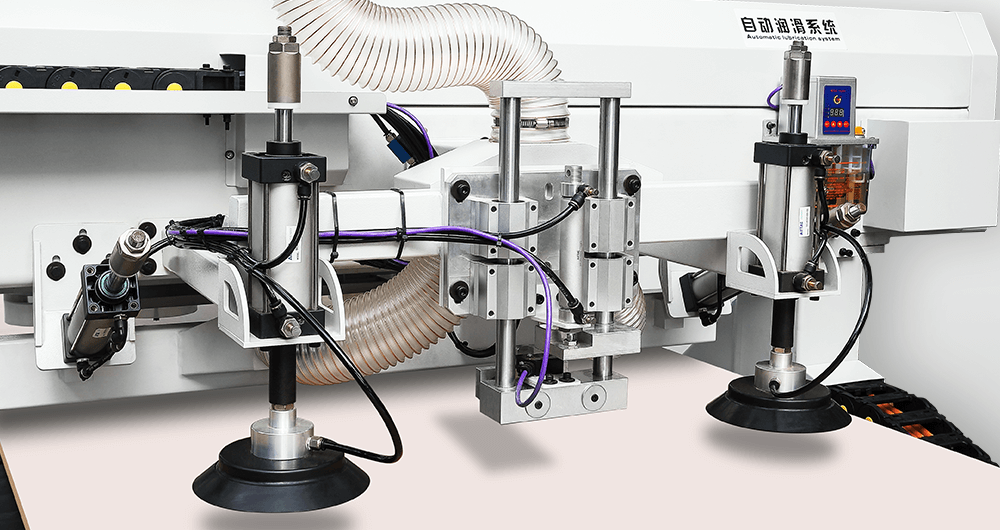

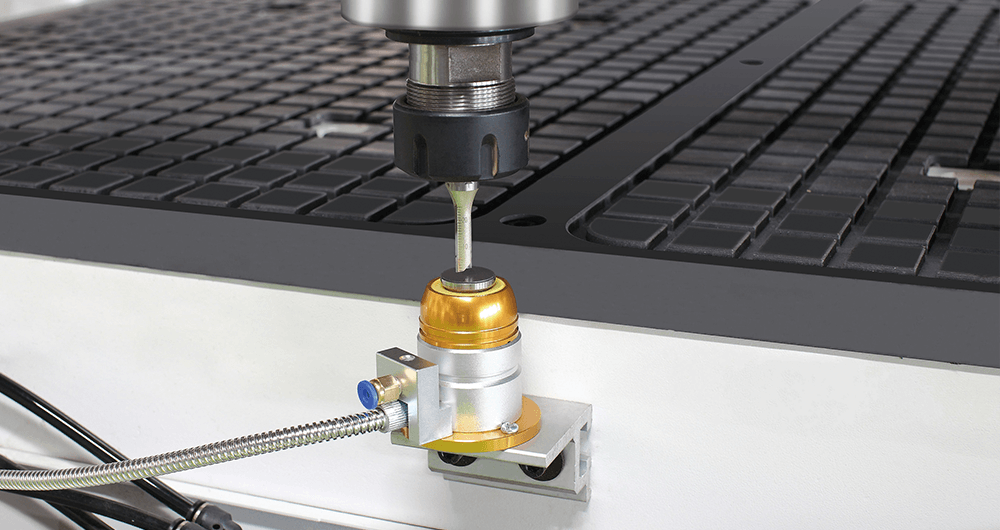

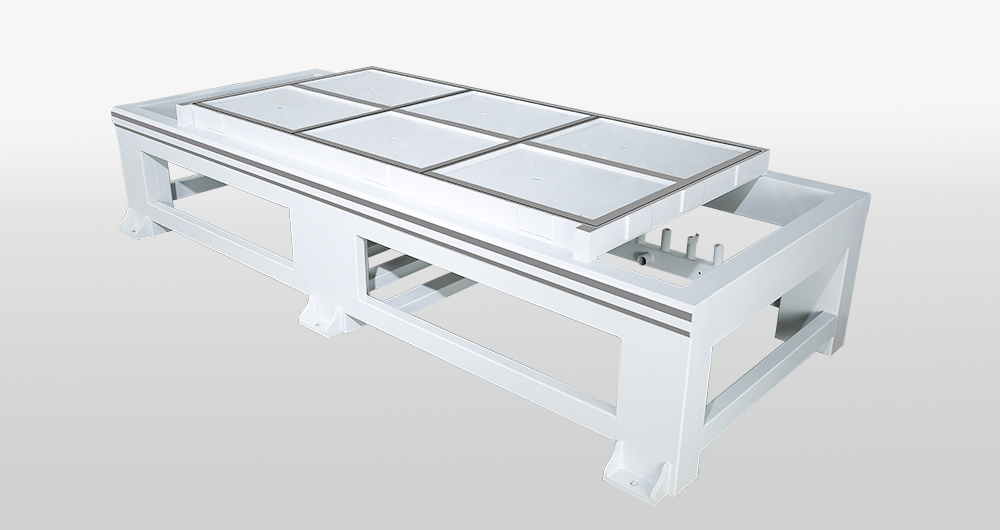

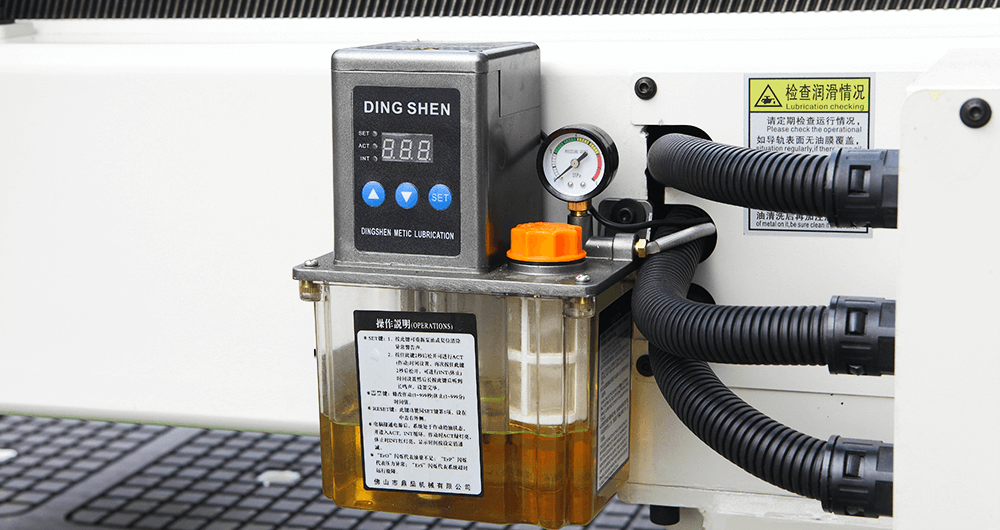

The TQS disc tool changing machining center is a widely used processing center for milling cabinet door panels and cutting and drilling board furniture. The main features of this model are: it is equipped with a high-efficiency servo tool magazine, with precise and high-speed tool position positioning, a 16-tool capacity tool magazine (optional 32-tool double tool magazine), and it can achieve automatic tool changing function. It is suitable for multiple industries, such as woodworking, advertising, and handicrafts, and can easily process various furniture such as doors, windows, cabinets, craft wooden doors, paint-free doors, screens, craft fan windows, rosewood furniture, and wavy boards.

Equipment highlights

Technical information

| TN-3409E | ||

|---|---|---|

| Effective processing stroke *[mm] | X:1220 Y:2800 Z:200 | |

| Feeding height *[mm] | 70 | |

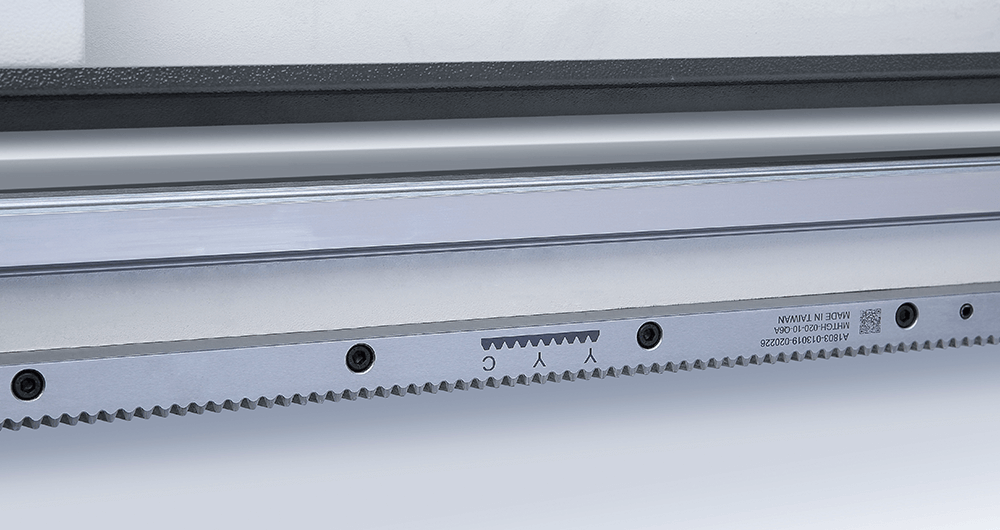

| Machining accuracy *[mm] Repeatability positioning accuracy *[mm] | 0.15 0.05 | |

| Maximum cutting speed *[mm/min] | 15000-20000 | |

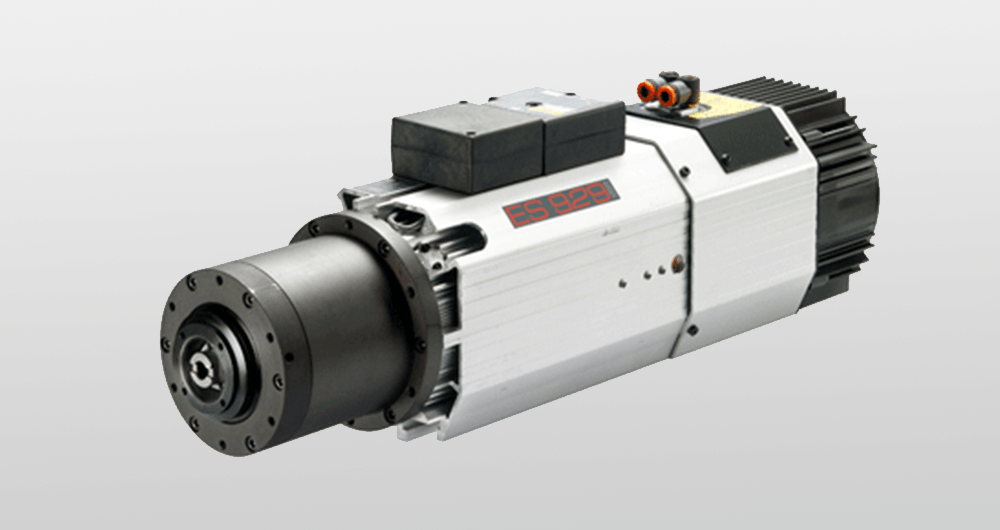

| Main shaft power *[kW] Spindle speed *[r/min] | 9 24000 | |

| Tool magazine capacity | 16 | |

*For more technical information, please download and view the relevant documents.

*Technical information may be subject to change!