TQS-610-C4AP

Ideal equipment for drilling holes on the side of sheet metal parts

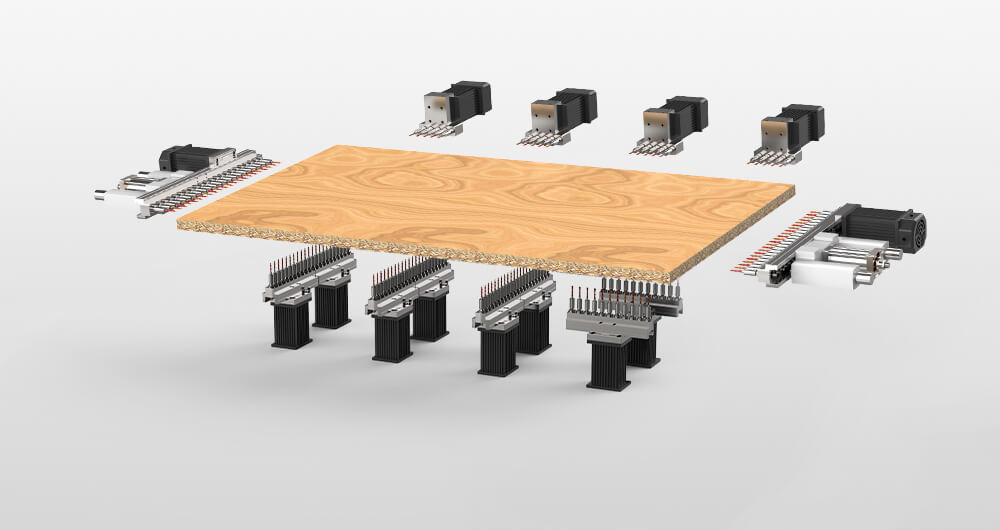

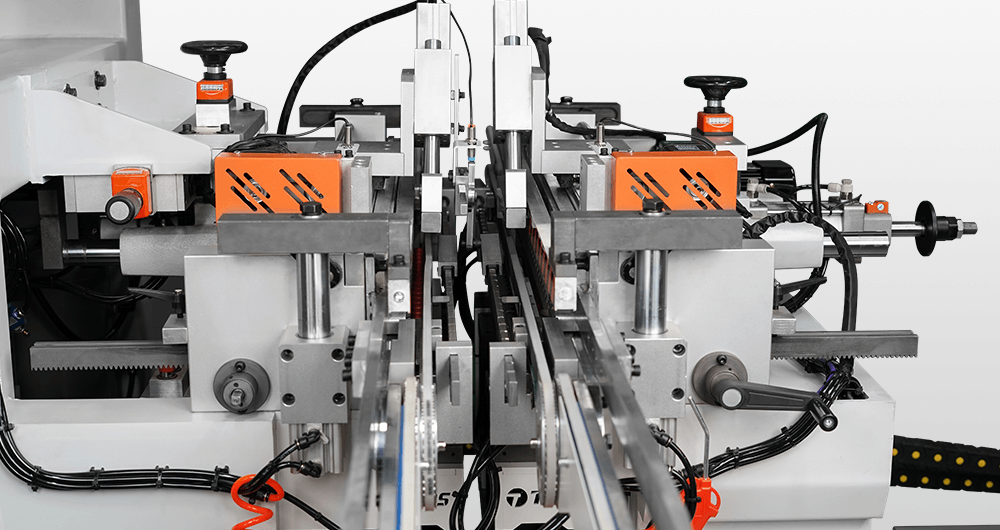

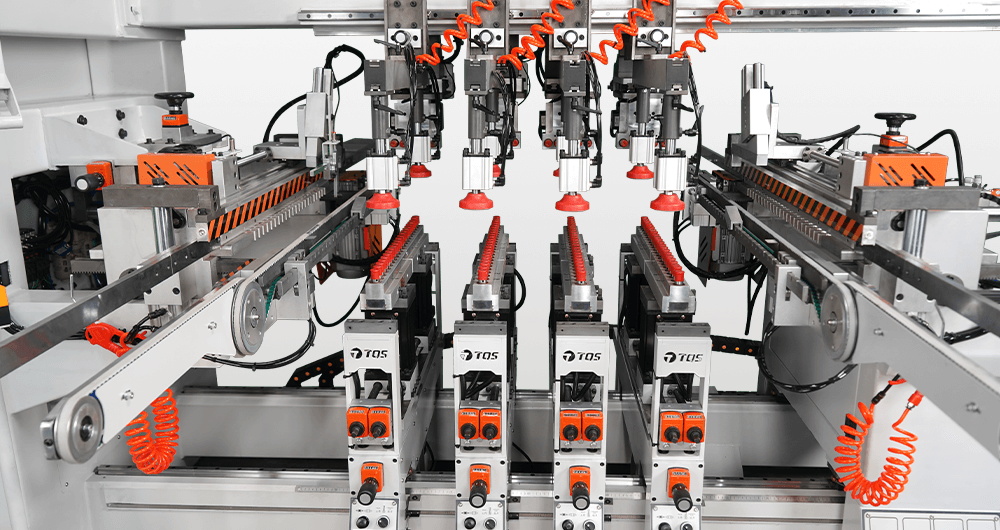

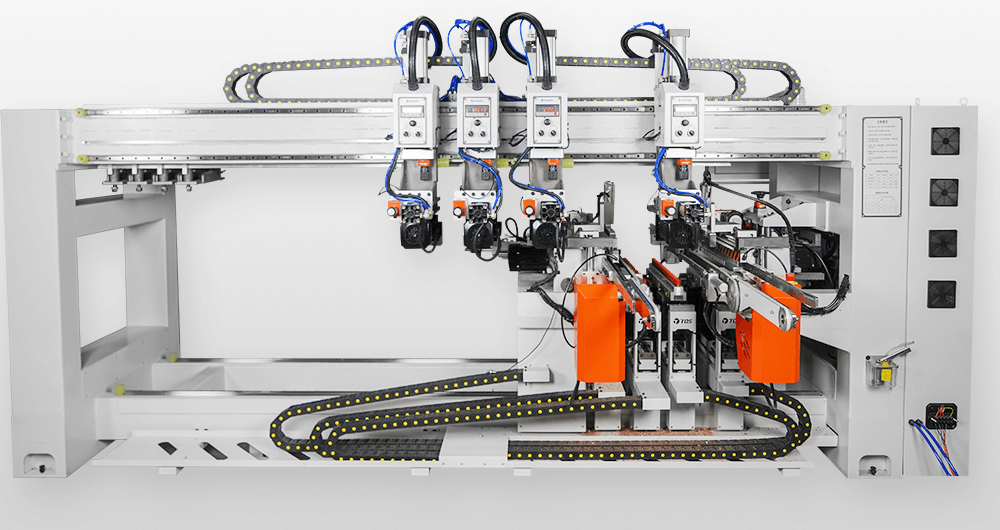

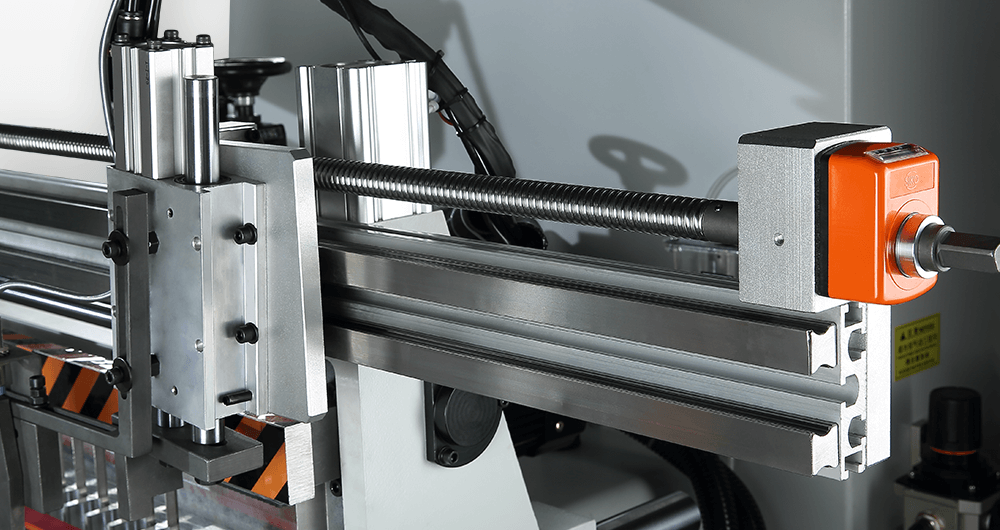

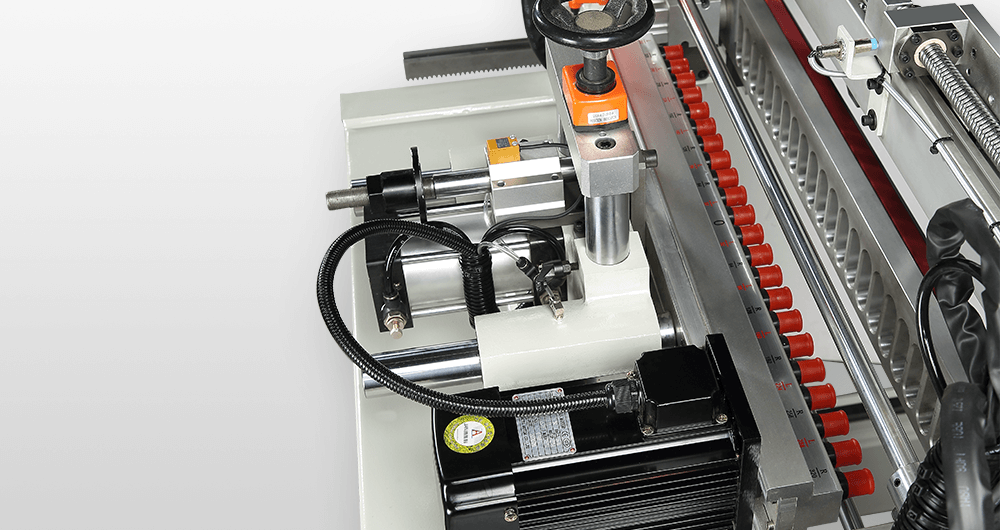

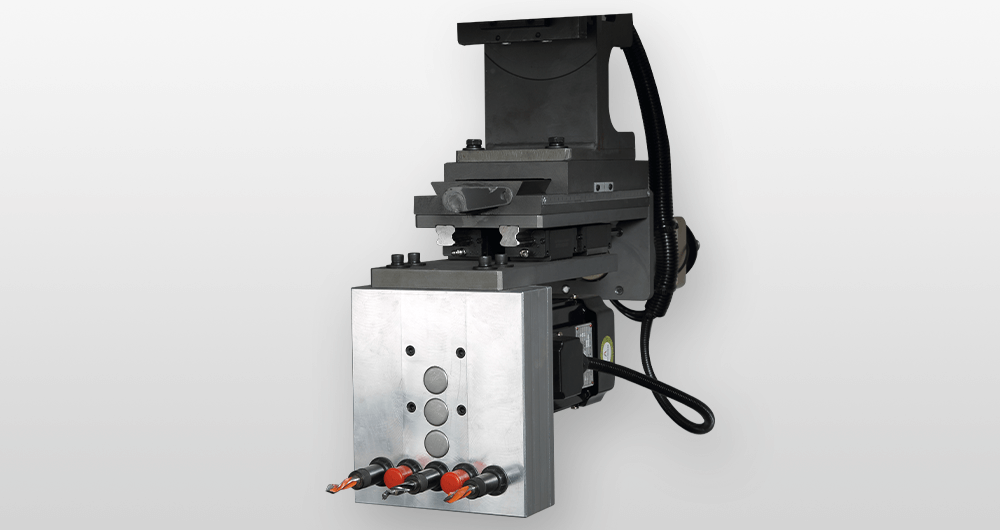

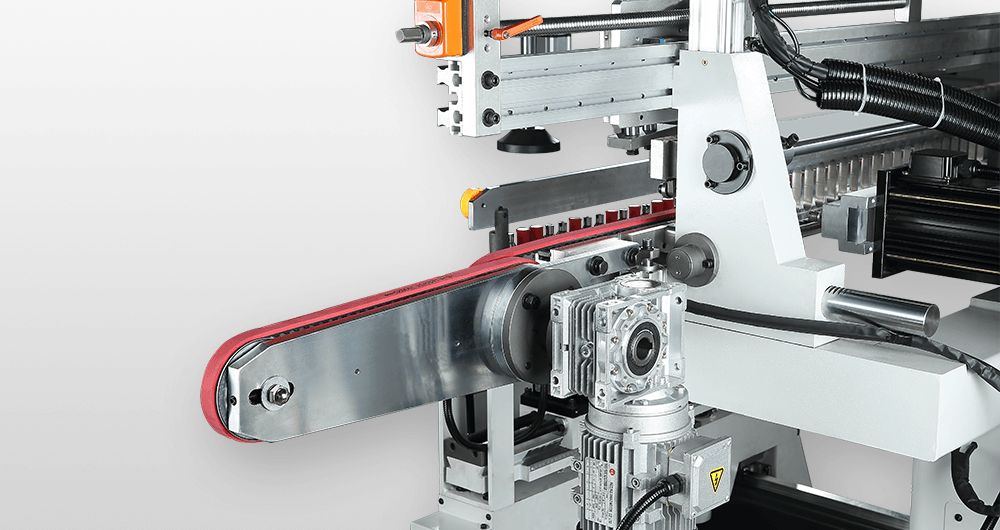

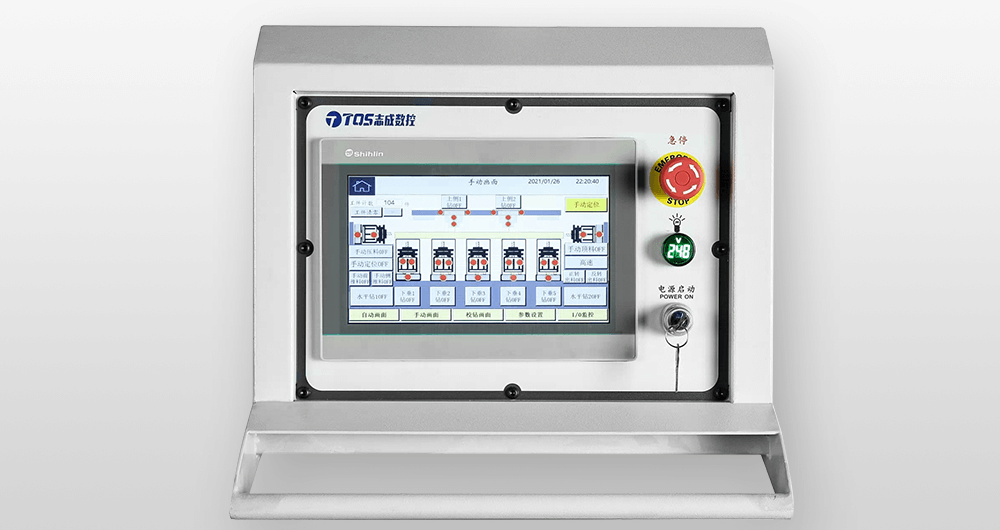

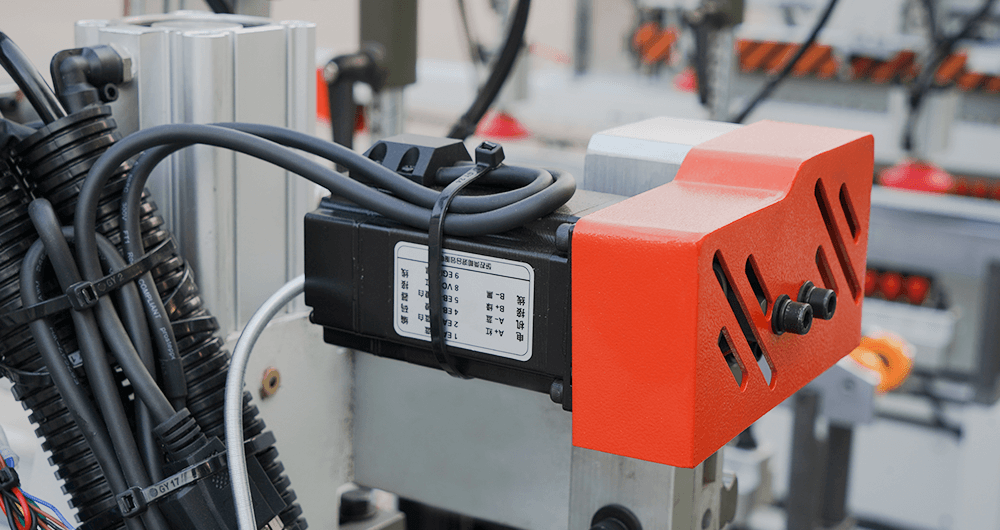

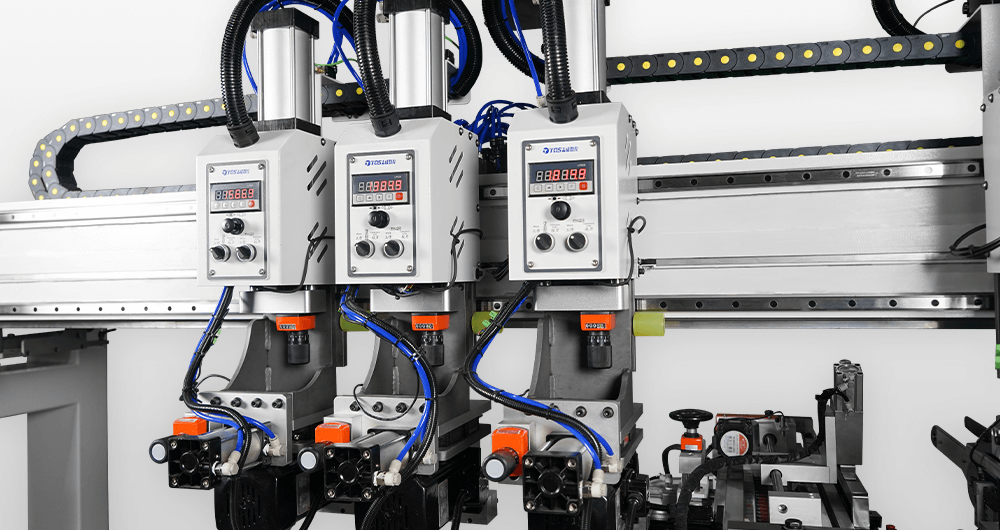

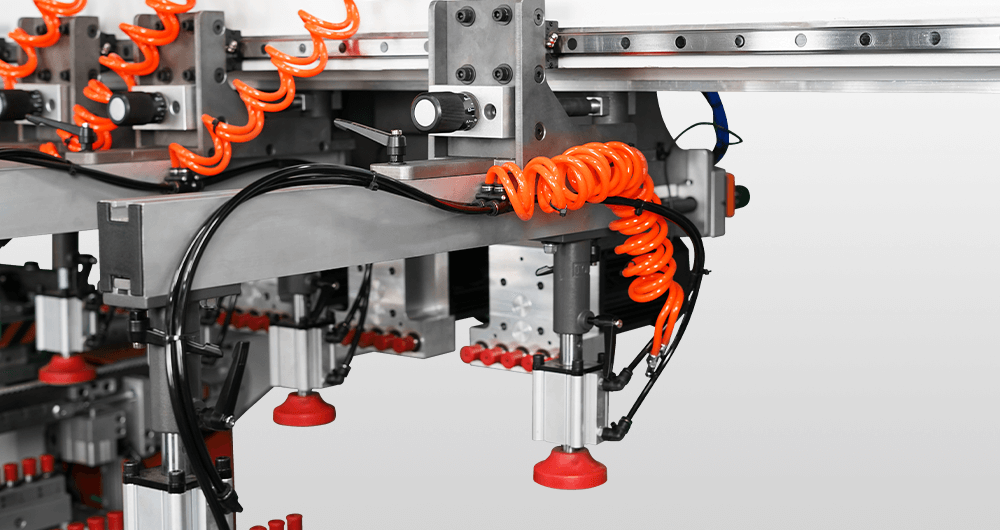

This is suitable for completing the four-sided drilling operation in one process during the production of panel furniture. The upper rear side drilling row, the left and right horizontal drilling rows, and the lower vertical drilling row can be freely combined for work. It can process up to 13-16 panels per minute. It adopts a belt transmission feeding method and is equipped with a ball screw transmission positioning device to ensure precise positioning. The upper and lower vertical drilling rows are equipped with digital displays, and it is controlled by a logic control programming PLC system.

Equipment highlights

Technical information

| TQS-610-C4AP | ||

|---|---|---|

| Processed sheet length *[mm] | 350mm - 2450mm | |

| Thickness of processed sheet material *[mm] | 8mm - 40mm | |

| Maximum drilling depth *[mm] | 40 | |

| The number of vertical side hole drilling rows on the upper part | 4 | |

| Number of vertical drill rows downward | 4 | |

| Number of left/right horizontal drill rows | 1/1 | |

| Total number of drill shafts | 152 | |

| Maximum drilling diameter *[mm] | 13(Adjacent drilling),35(Single drill bit) | |

| Y-axis hole pitch *[mm] | 32 - 672 | |

| Spacing of holes on the X-axis *[mm] | 350 - 2450 | |

| Processing speed *[件/min] | 13-16 | |

| Total power *[kW] | 21 | |

*For more technical information, please download and view the relevant documents.

*Technical information may be subject to change!