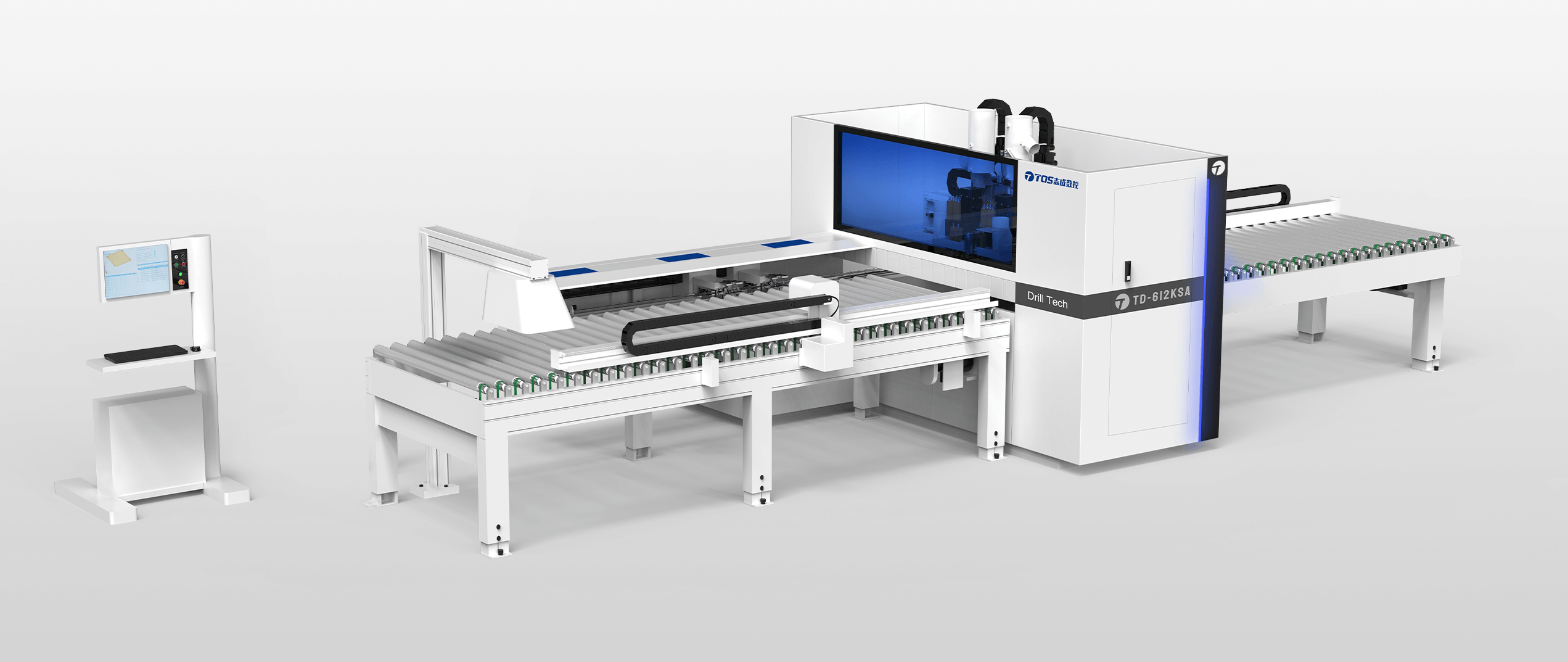

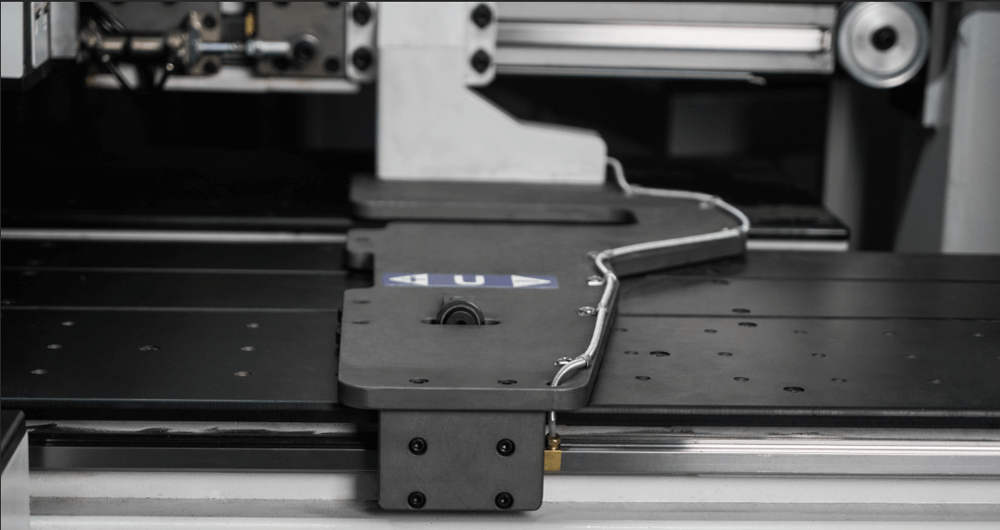

DRILLMAC H-612KSA

Automatic scanning for material input and automatic processing

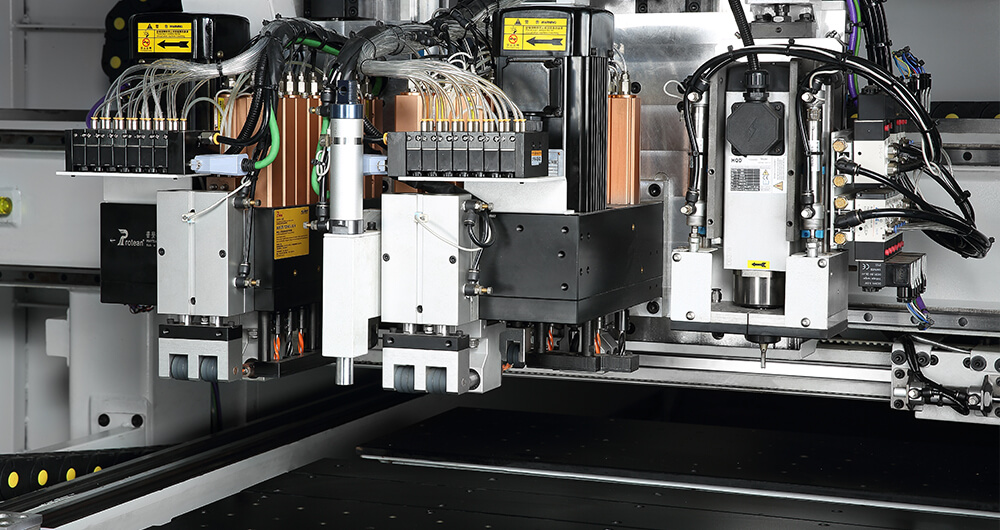

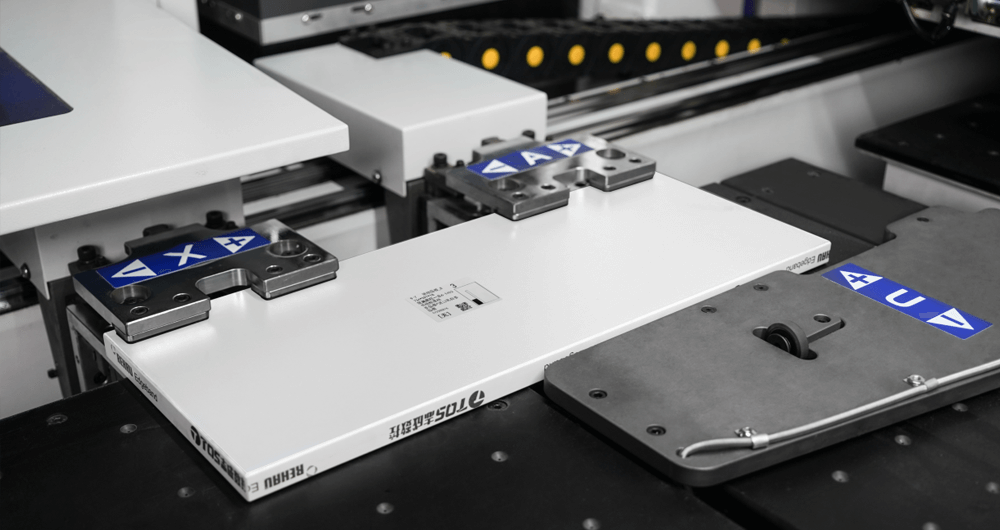

The automatic feeding system scans and reads the processing program of the sheet metal. The clamps feed the sheet metal into the processing unit at a speed of 135m/min and automatically detect the relevant dimensions of the sheet metal to prevent errors. The processing unit's dual drill packages synchronously process symmetrical holes, doubling the processing speed. Each hole is drilled with extremely high repeatability accuracy, and the same applies to milling and slotting processing. Its degree of automation can be easily combined with other machinery to achieve various connection methods.

Equipment highlights

Technical information

| DRILLMAC H-612KSA | |

|---|---|

| Maximum width of sheet (vertical) *[mm] | 1200 |

| Minimum width of sheet (vertical) *[mm] | 35 |

| Maximum length of the sheet (vertical) *[mm] | 5000 |

| Minimum length of sheet (vertical) *[mm] | 70 |

| Maximum thickness of sheet (vertical) *[mm] | 50 |

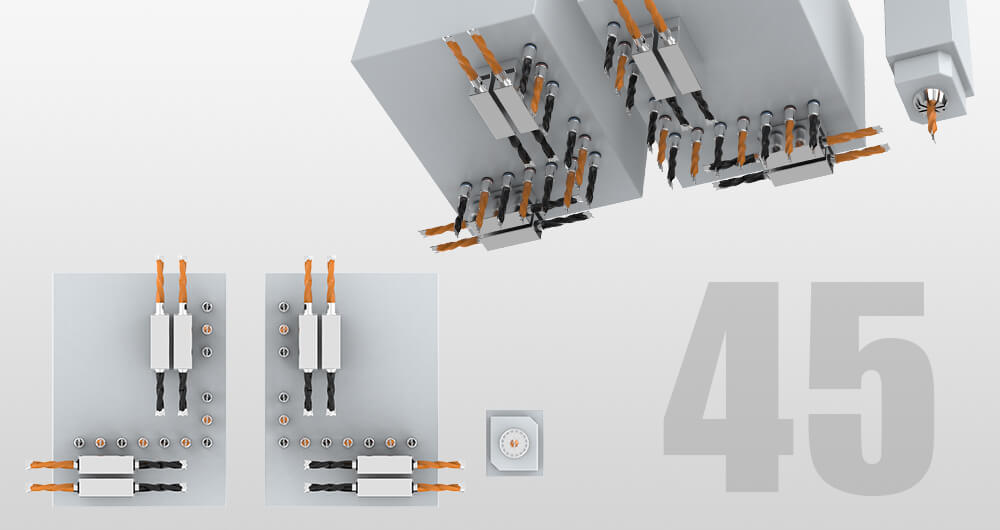

| Drilling combination device | |

| Vertical drilling axis | Up:24 Below:9 |

| Horizontal drilling shaft | 16 |

| Drill group motor speed *[r/min] | 3400 |

| Main shaft power *[kW] | 2 x 3.5 |

| L *[mm] | 7500 |

| W *[mm] | 2800 |

| H1 *[mm] | 1900 |

| H2 *[mm] | 2200 |

| Total power *[kW] | 27.75 |

*For more technical information, please download and view the relevant documents.

*Technical information may be subject to change!