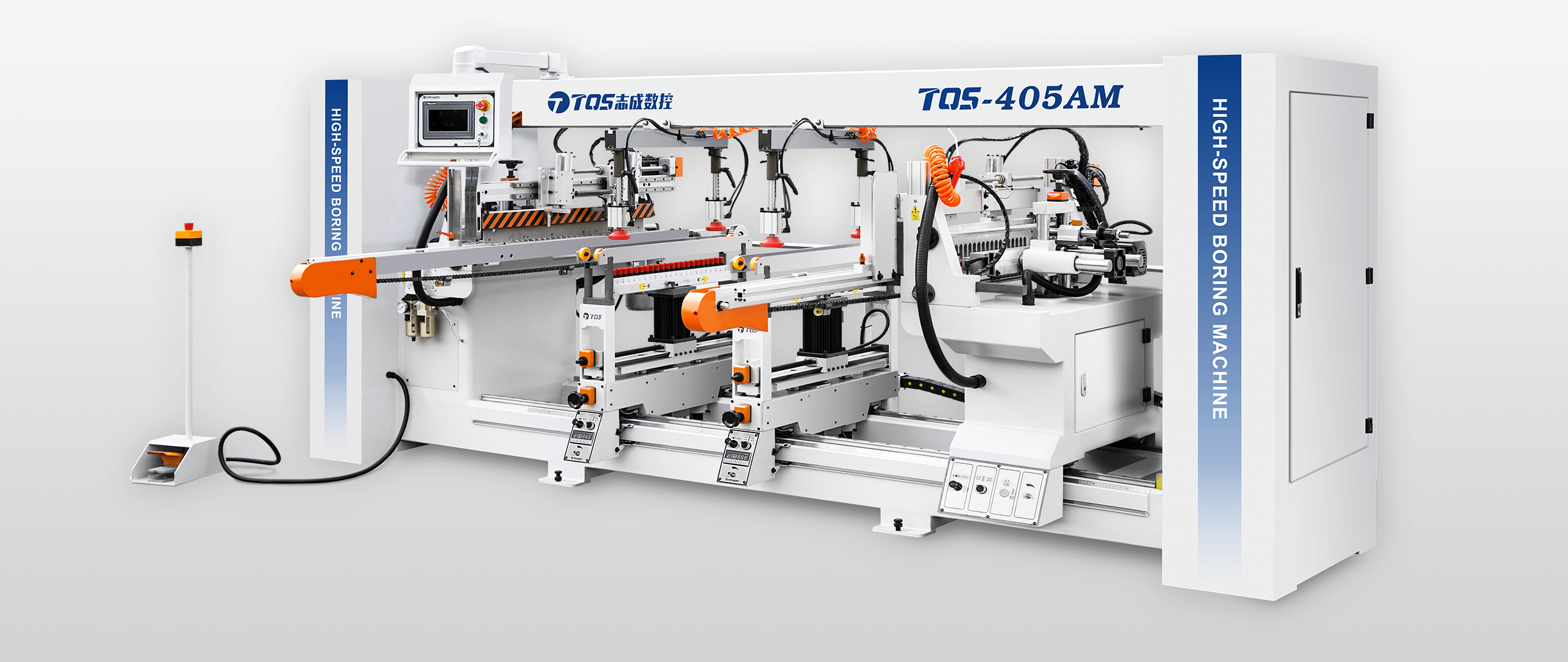

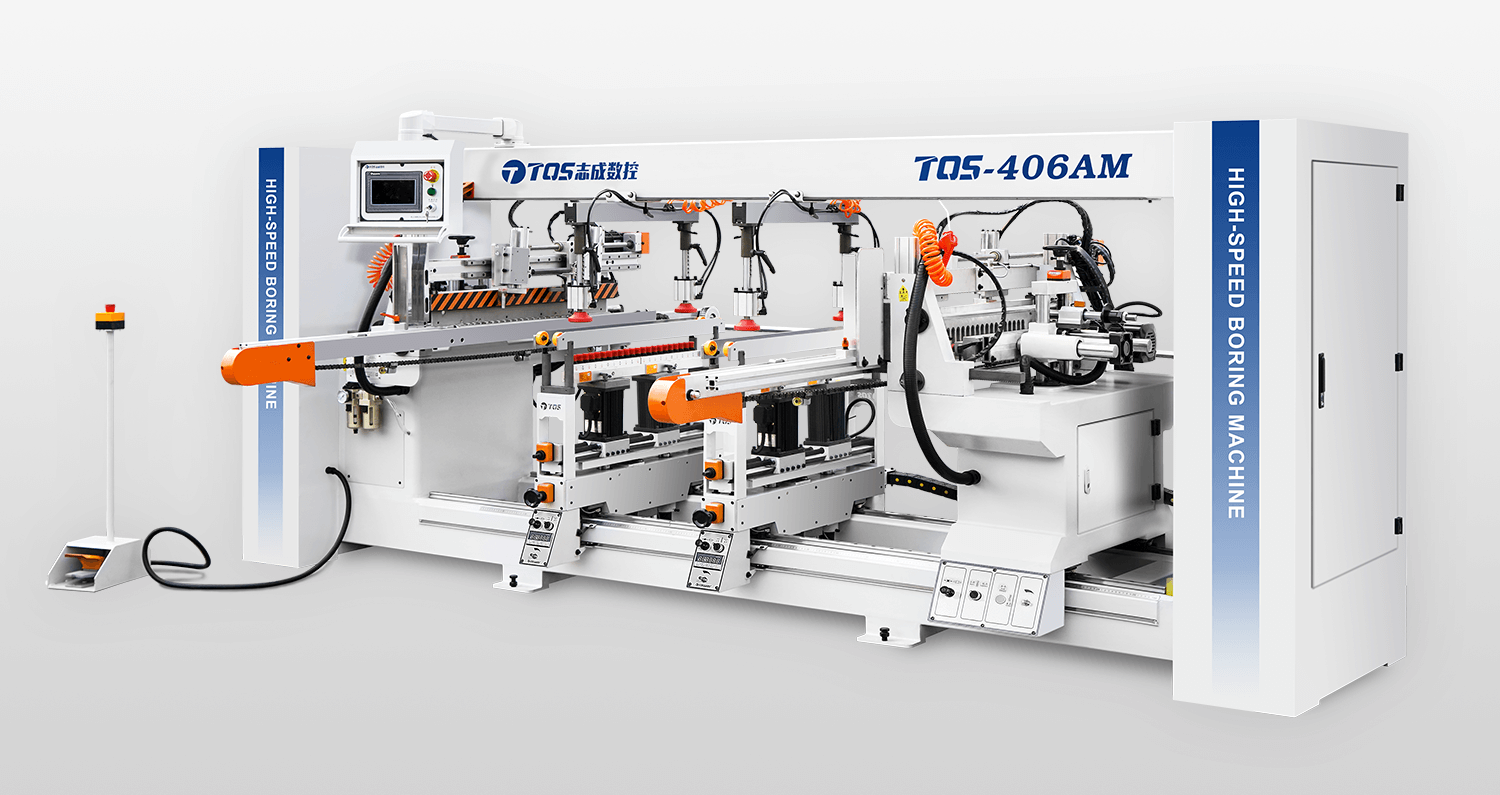

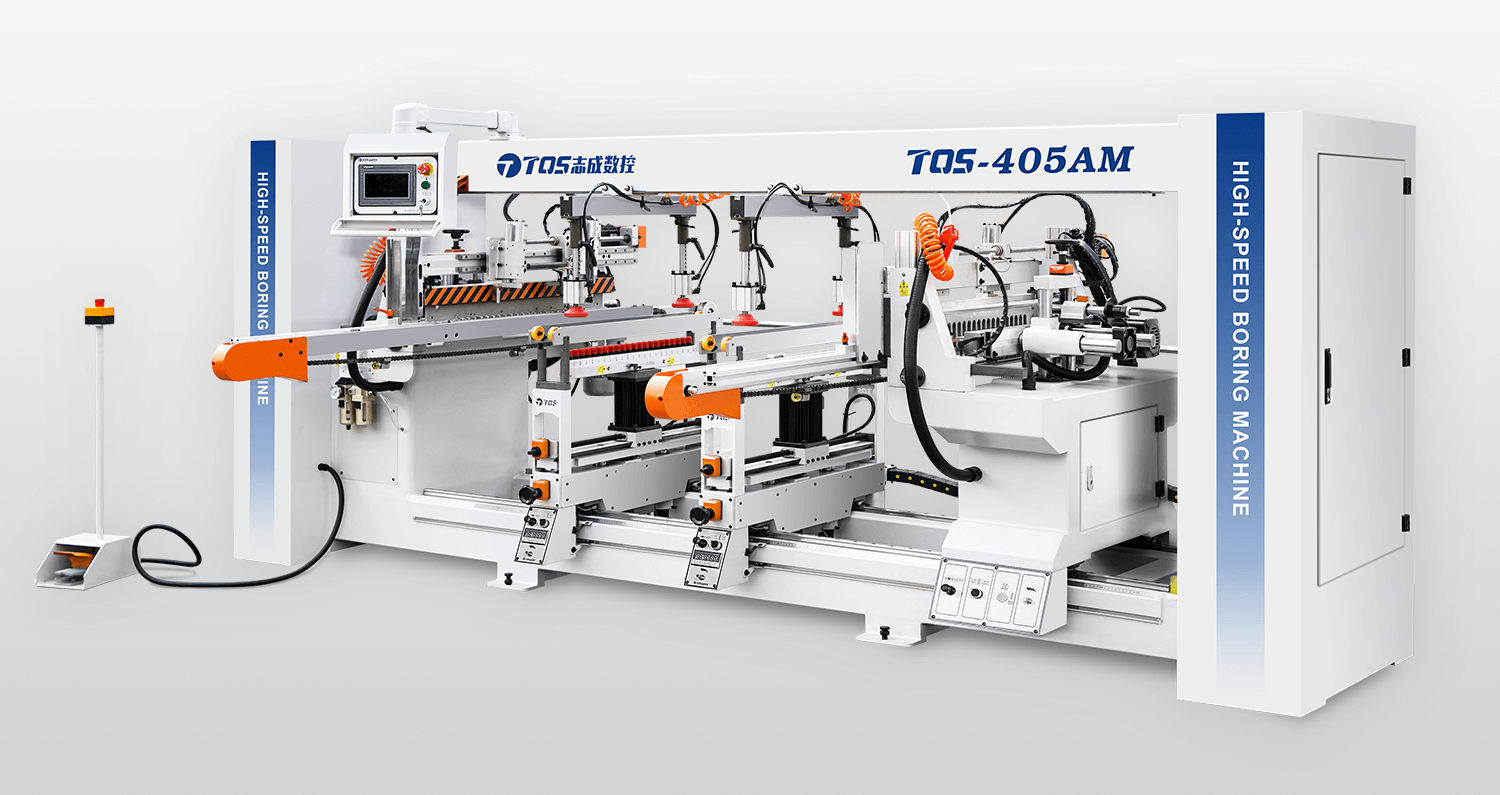

TQS-406/405AM

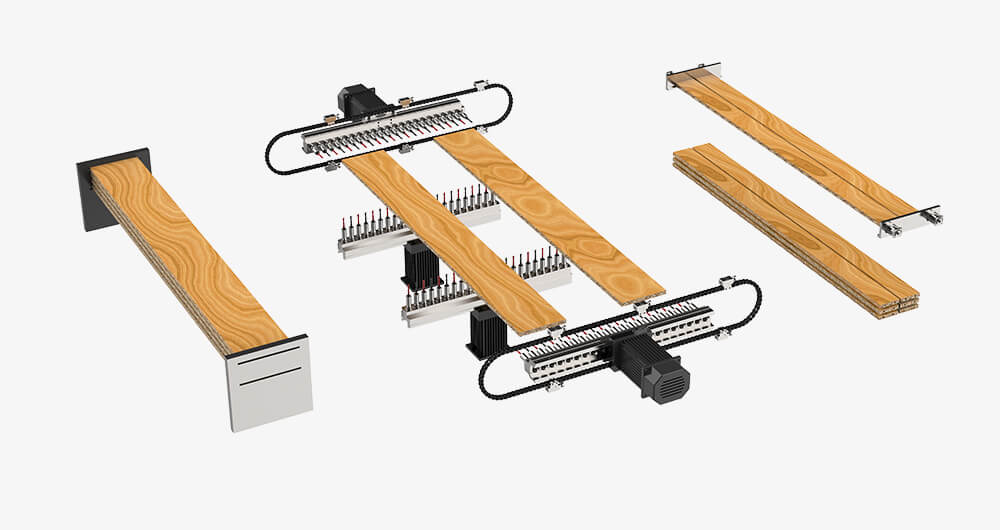

Batch processing of drawer panel drilling technology

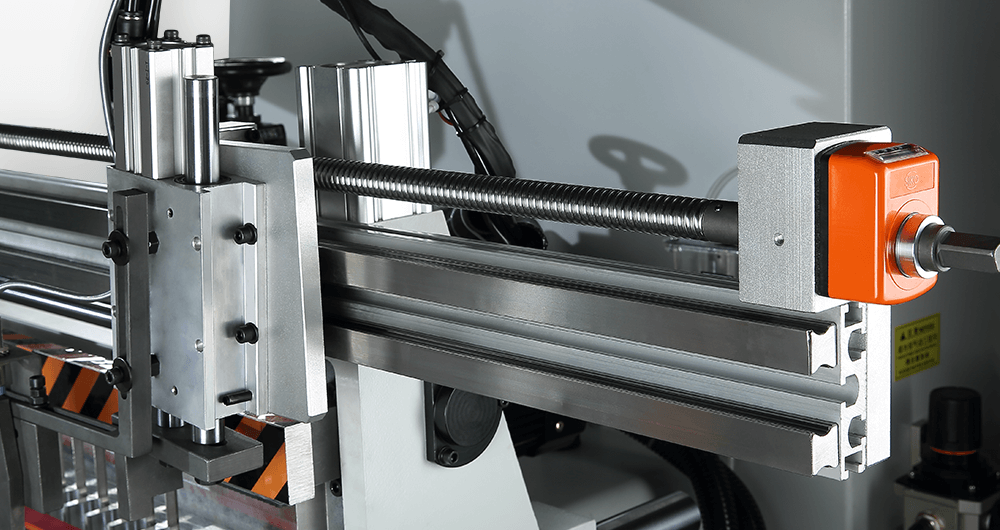

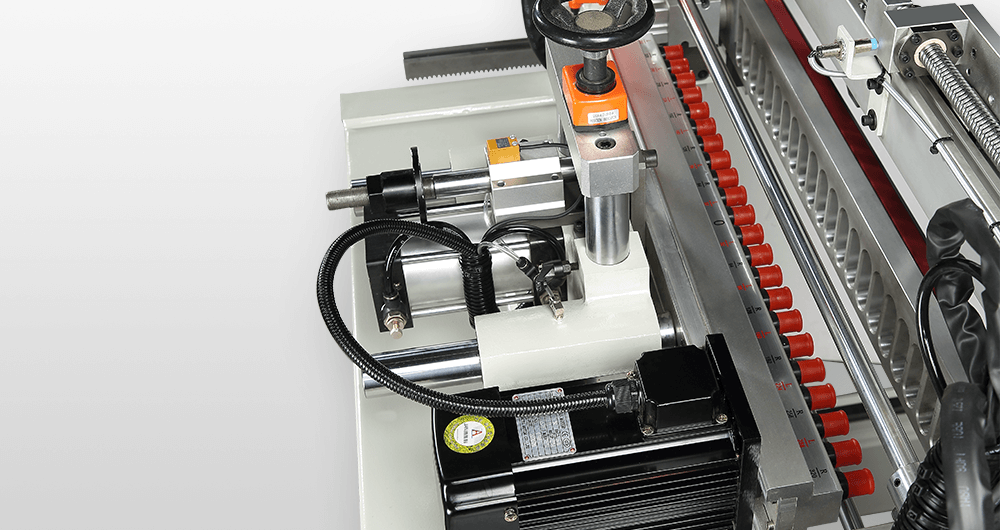

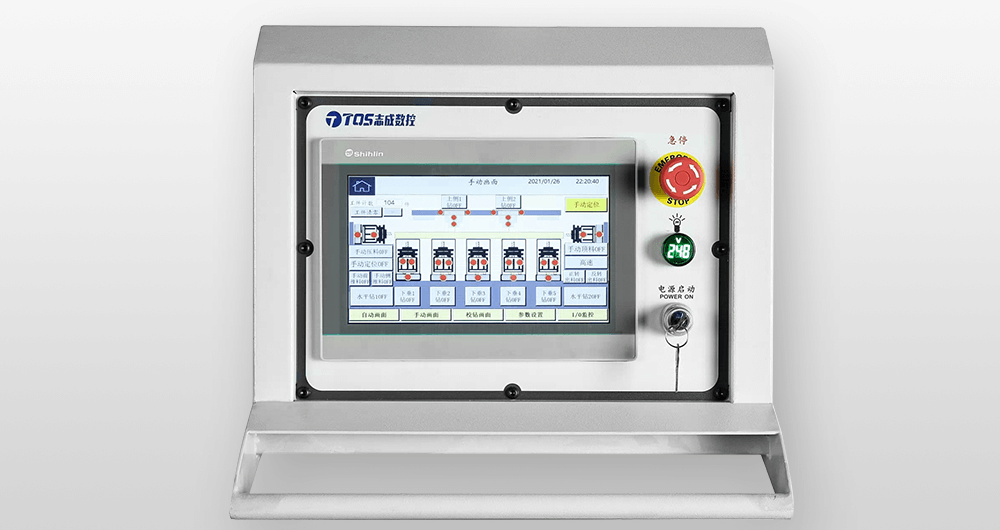

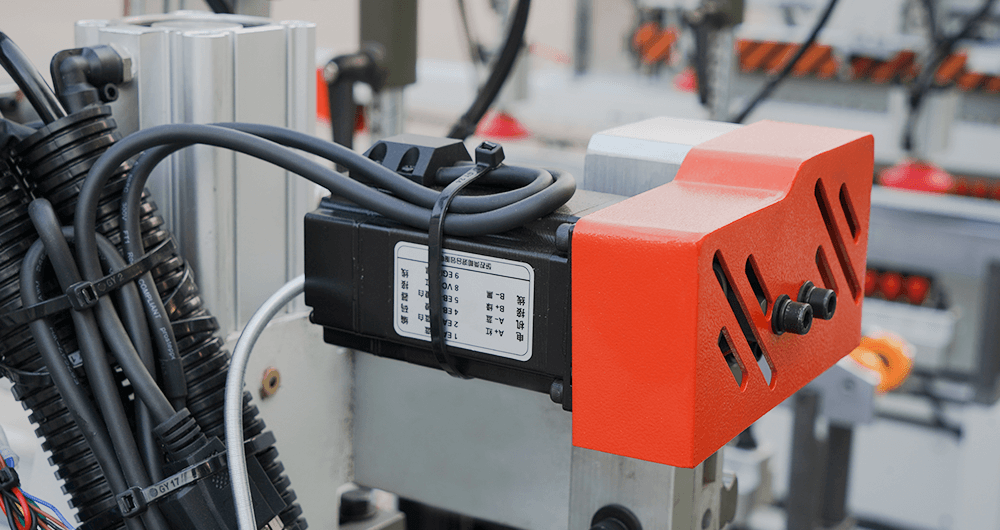

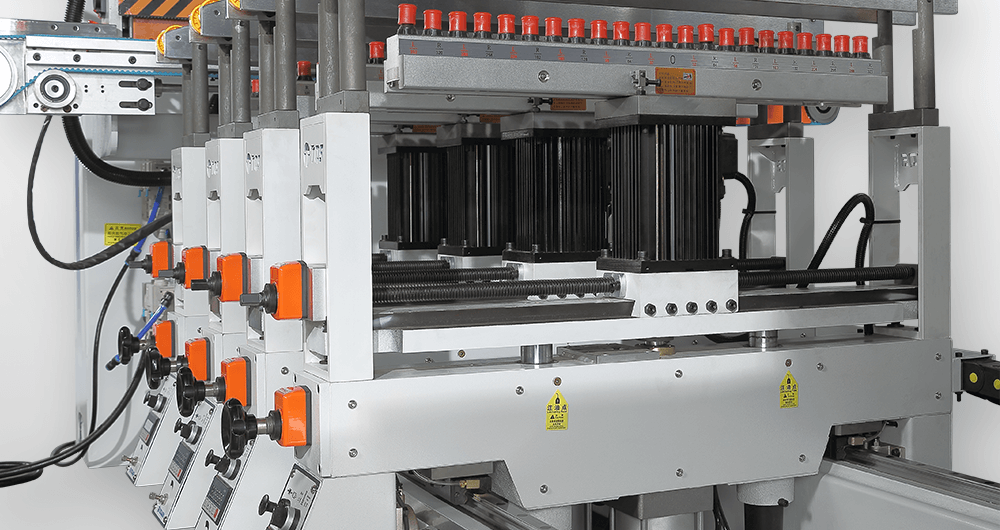

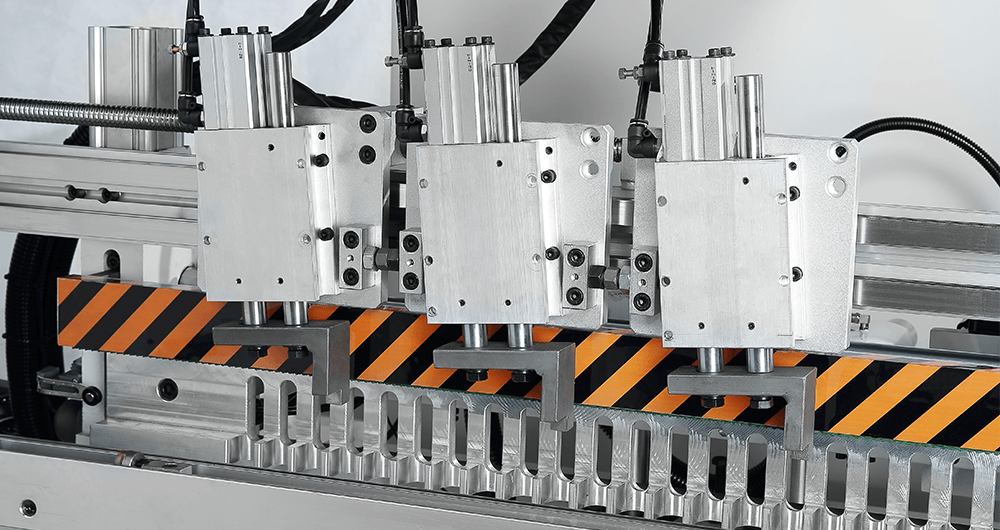

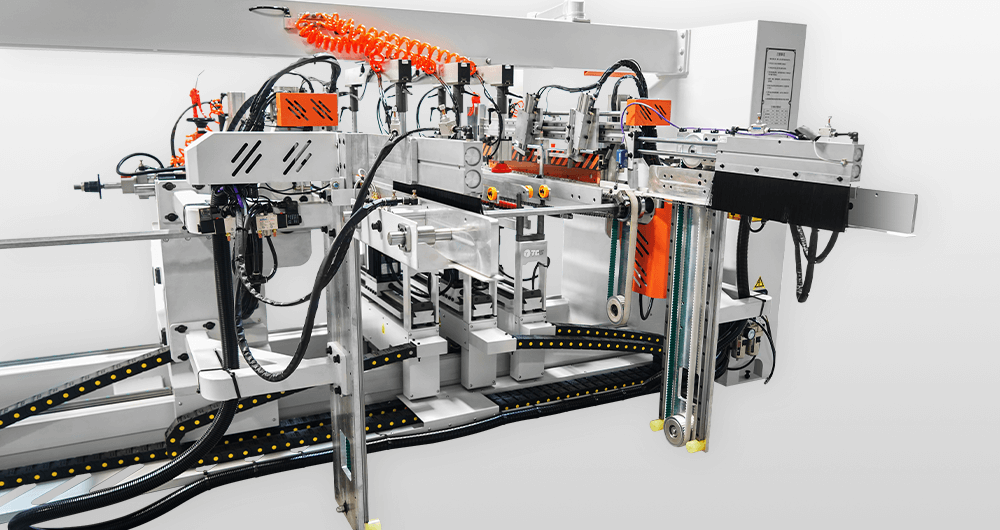

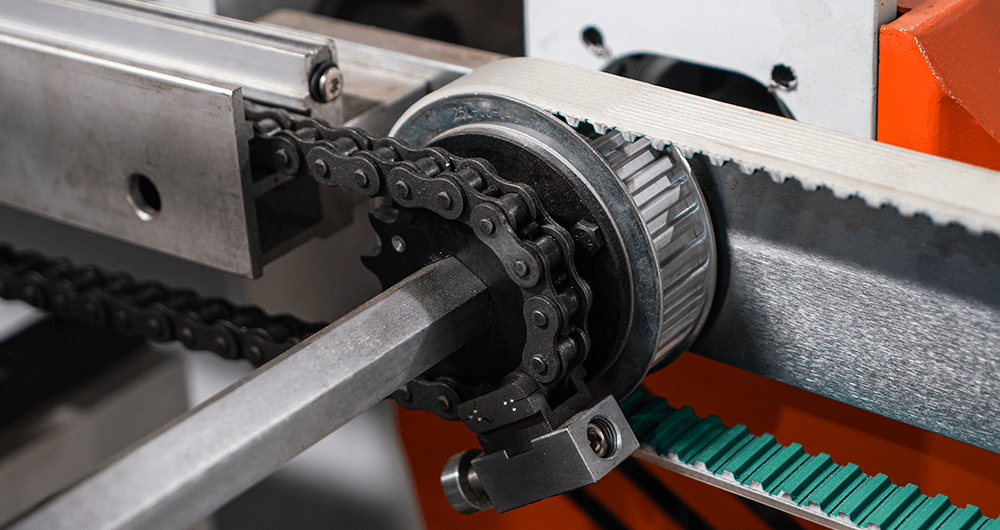

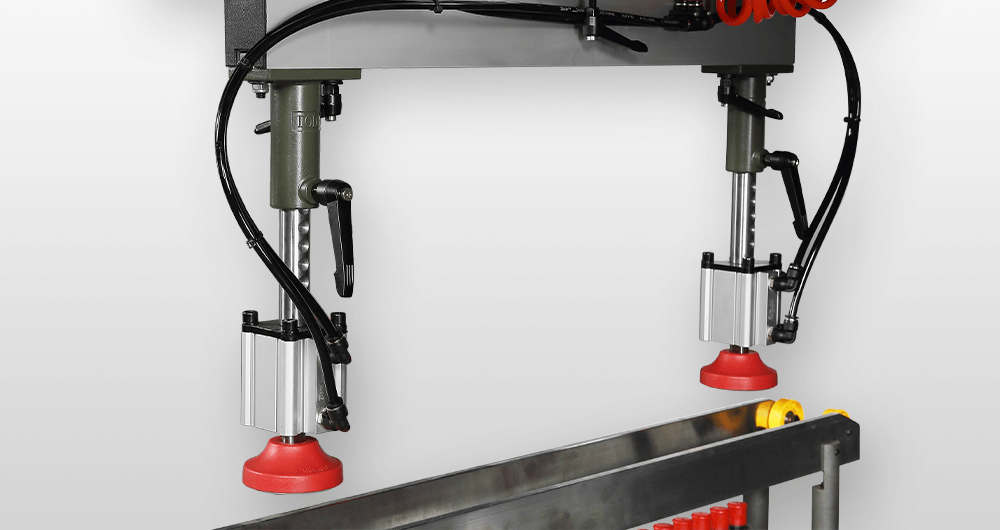

This is suitable for completing three-sided drilling operations in one process during the production of panel furniture. It is equipped with a built-in stack material warehouse to achieve automatic feeding. It is standard with double positioning processing (optional triple positioning), capable of processing 2-3 pieces of board at one time. The left and right horizontal drilling rows and the lower vertical drilling row can be freely combined for work. It adopts a chain transmission method and is equipped with a ball screw transmission positioning device to ensure precise positioning. The vertical drilling row is equipped with a digital display, and it is controlled by a logic control programming PLC system.

Drill bit arrangement: 1 horizontal drill bit row on the left, 1 horizontal drill bit on the right, and 2 vertical drill bit rows at the bottom.

( Batch high-speed drilling machine AM series)

Equipment highlights

Technical information

| TQS-406AM | TQS-405AM | |

|---|---|---|

| Processed sheet length *[mm] | 220 – 2450 | |

| Thickness of processed sheet material *[mm] Single board processing width Double-board processing width Three-board processing width | 35-670 35-320 35-150 | |

| Maximum drilling depth *[mm] | 40 | |

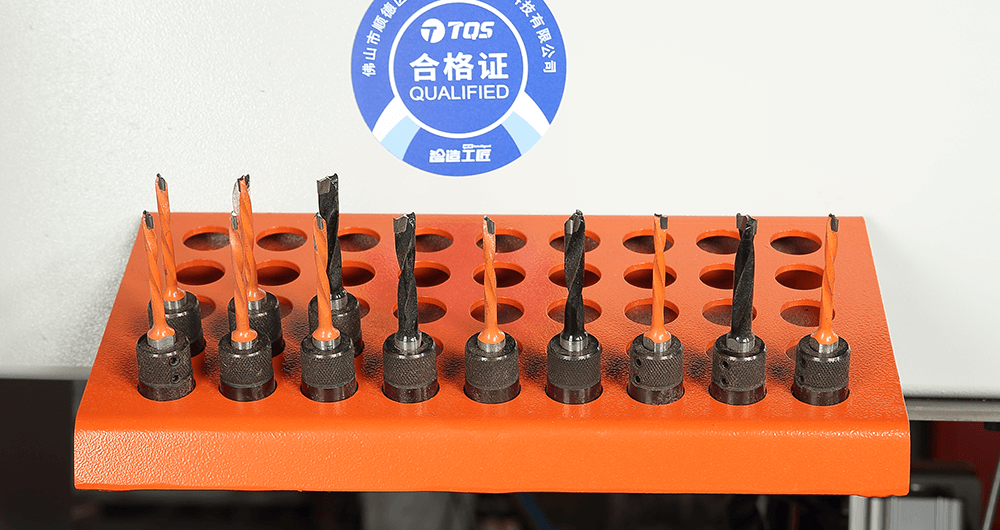

| Maximum drilling diameter *[mm] | 13(Adjacent drilling),35(Single drill bit) | |

| Y-axis hole pitch *[mm] | 32 - 672 | |

| Spacing of holes on the X-axis *[mm] | 220 - 2450 | |

| Processing speed *[pcs/min] Single-board processing speed Double-board processing speed Three-board processing speed | 13-16 20-26 36-40 | |

| Total number of drill shafts | 88 | |

| Total power *[kW] | 9 | 6 |

*For more technical information, please download and view the relevant documents.

*Technical information may be subject to change!