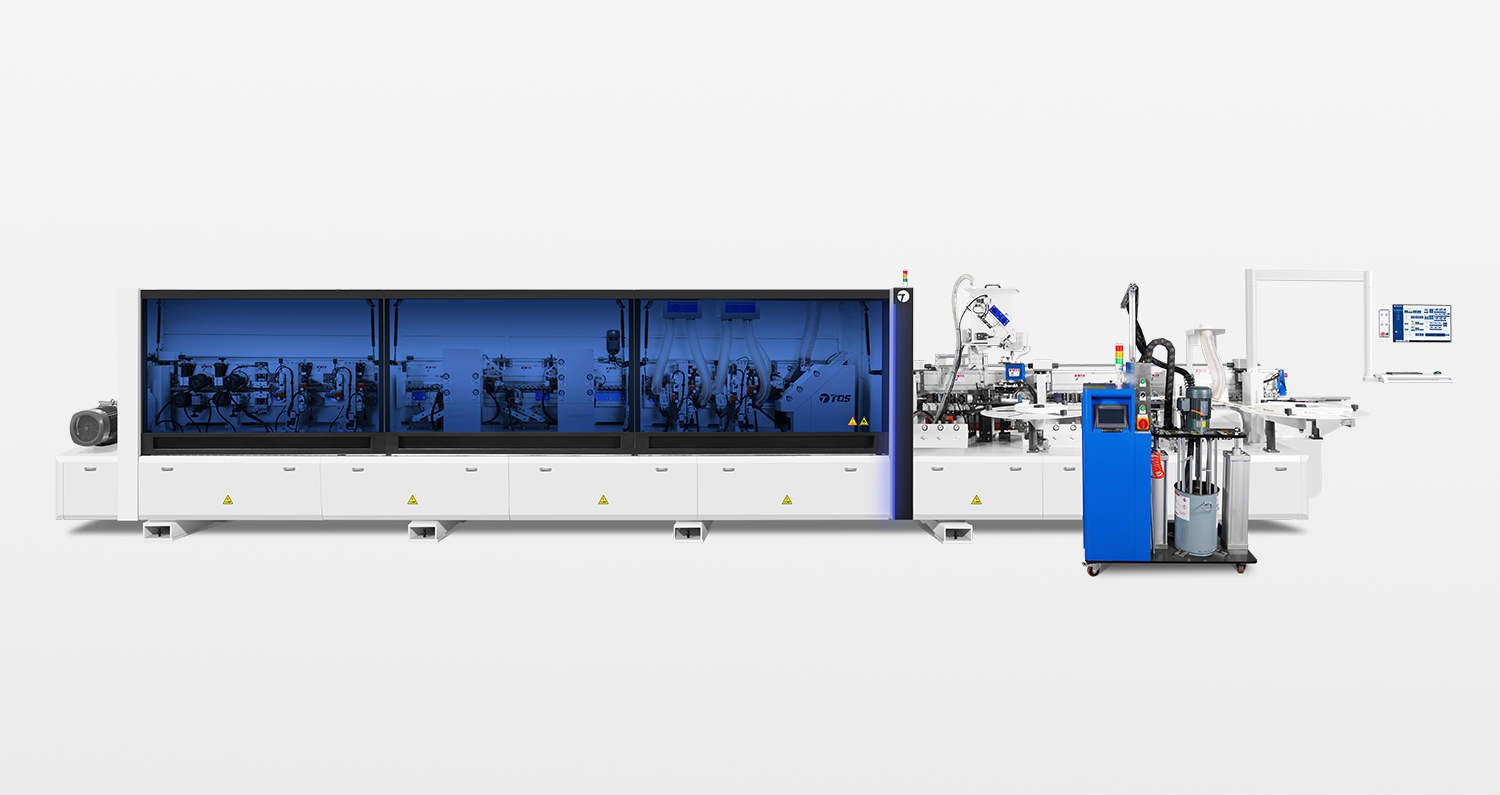

EDGEMAC E-370A

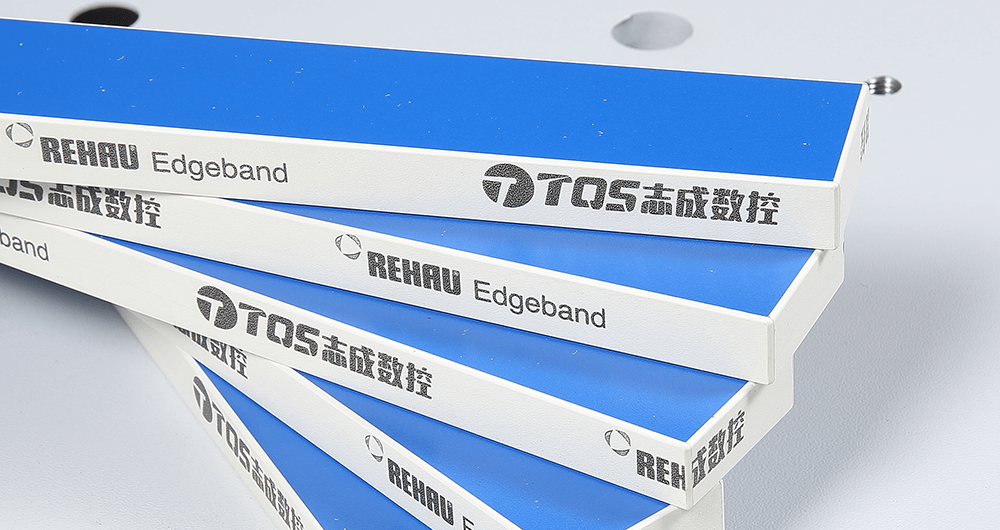

40mm narrow edge end sealing - Fearless of narrow edges, quality edge sealing

Fearless of narrow edges, quality edge banding, efficiency and quality both achieved - easily handle 40mm narrow boards, after processing the narrow board end and the long strip edge banding seamlessly integrate, efficiently solve the problem of high-quality narrow small board and end edge banding effect.

( Feed speed: 16m - 26m/min)

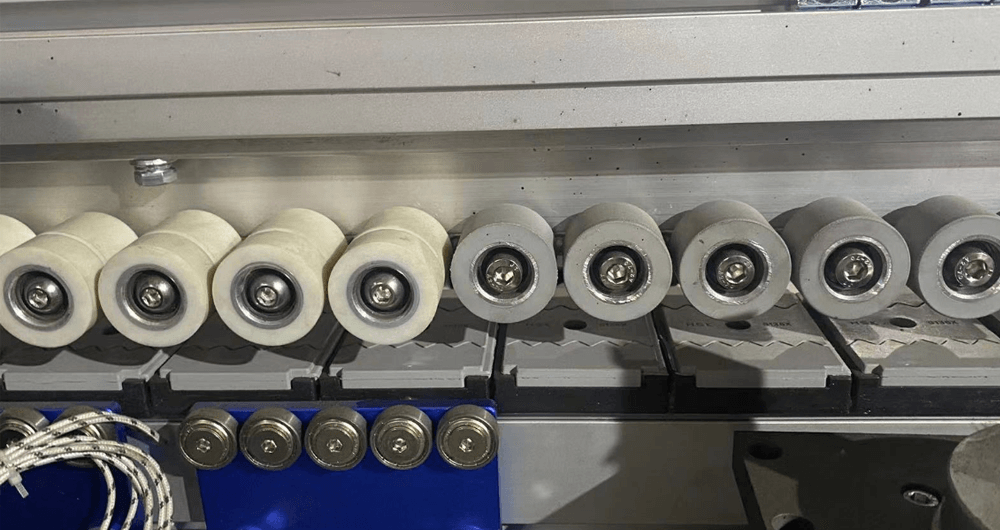

Equipment units: separator, pre-milling, baking lamp, no-clean PUR system, upper rapid sol gel system, six-wheel pressure bonding conveyor belt, double guide rail alignment, rough trimming, pneumatic fine trimming 1, pneumatic fine trimming 2, four-blade profiling tracking, pneumatic fine scraping 1, pneumatic fine scraping 2, flat edge scraping, cleaning agent, polishing 1, polishing 2

Equipment highlights

- PC intelligent control - An excellent operating system with a graphical user interface, supporting seamless integration of scanned label information with the production management system.

- The integral frame - After the frame is welded, it undergoes multiple processes such as aging, annealing, shot peening, and five-axis machine tool processing to ensure processing accuracy and long-term operational stability.

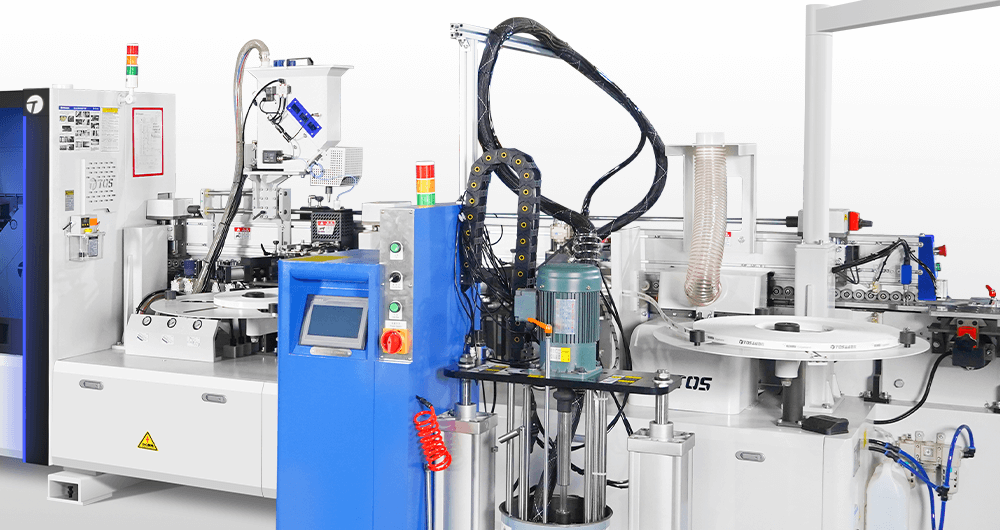

- The no-rinse PUR system, when paired with the top-mounted sol gel system, can be switched between PUR and EVA with a single button, meeting various edge banding requirements.

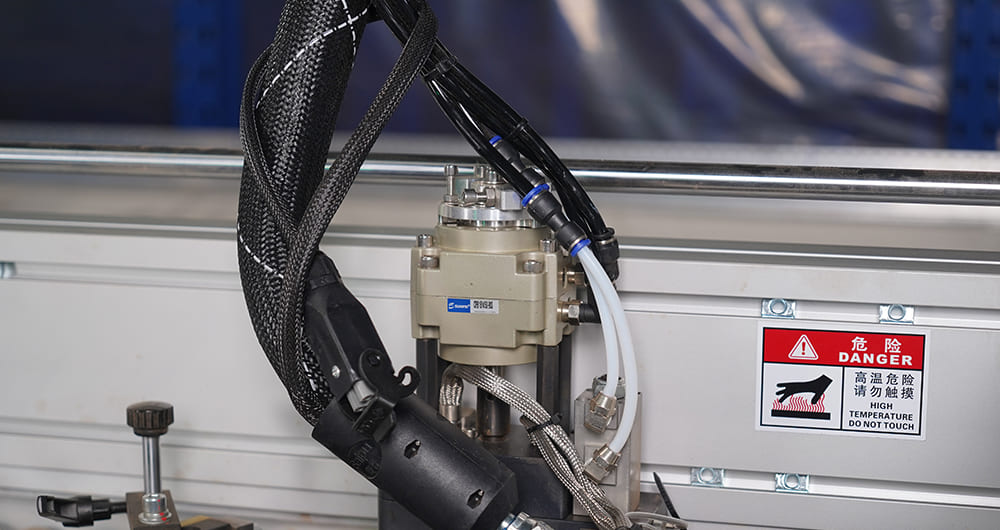

- Sealable PUR system without cleaning required - The sealed PUR upper solvent gel prevents air from entering and hardening the glue, reducing glue loss.

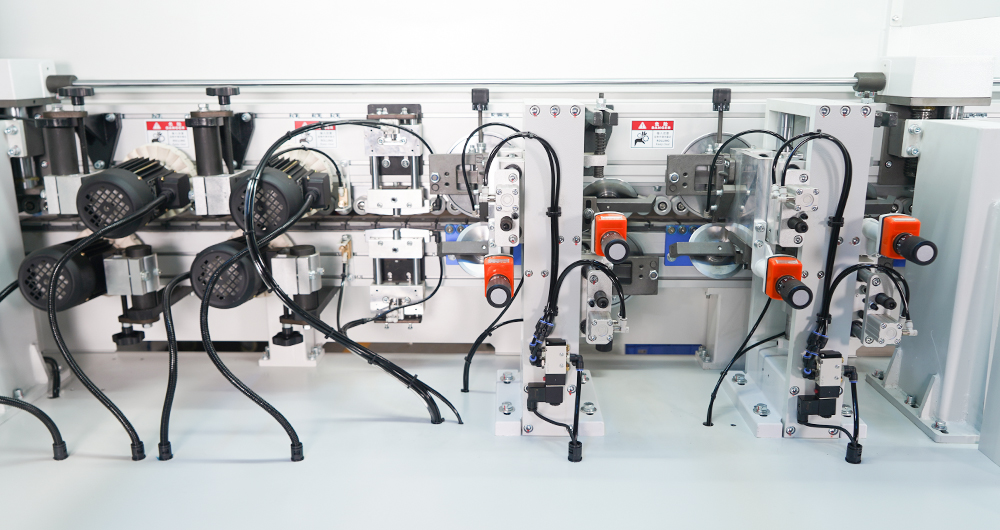

- Four-blade profiling tracking - capable of profiling and tracking the 45mm end and 40mm long side.

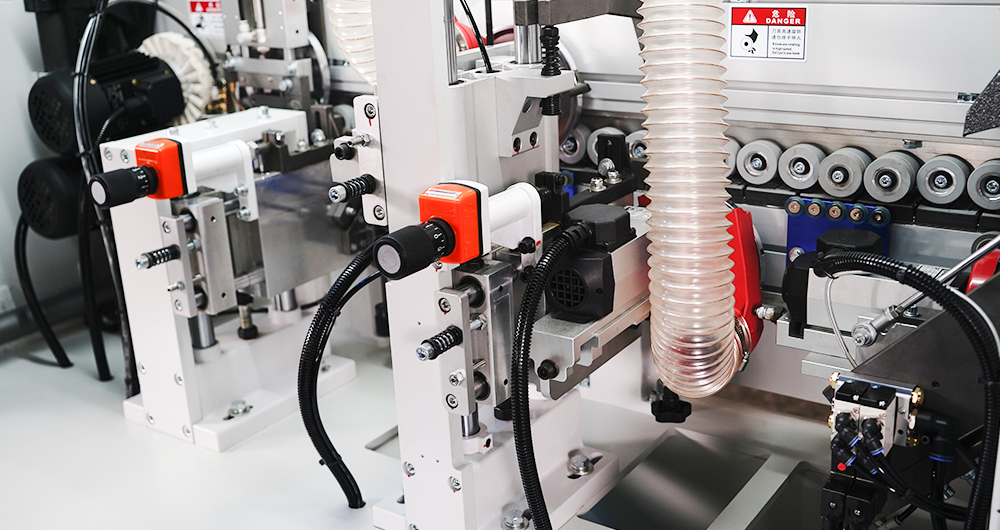

- Visualized pneumatic trimming and edge scraping - Electronic pneumatic control trimming and edge scraping knives, meeting the rapid switching requirements for thin and thick edge banding, reducing machine adjustment time.

- Auxiliary feeding device - Facilitates the smooth entry of narrow plates into the processing area, with convenient operation.

- Intelligent electric oil injection - Automatically lubricate the guide rails at regular intervals based on the machine's operating time.

40mm edge banding on the end

Intelligent edge banding machine industrial control system

A self-cleaning PUR system combined with an upper-mounted sol gel system

Visualized pneumatic double finishing

Four-blade high-speed profiling tracking device

Visualized pneumatic double edge scraping, flat edge scraping, and double polishing

Glaze-assisted support and pressure wheel

Technical information

| | EDGEMAC E-370A |

|---|

| Length of the board piece *[mm] | ≧120mm (Do not open tracking. Open tracking when it is greater than or equal to 300mm.) |

| Panel width *[mm] | ≥40mm |

| Panel thickness *[mm] | 9-60 |

Edge banding width *[mm]

| 12-65 |

Minimum sheet size *[mm]

| 300*40 (The 40mm end can be pre-milled, and the 300*40mm long side can be tracked.) |

Edge band thickness *[mm]

| 0.4-3 |

| Feed rate *[m/min] | 16-28 |

| Total power *[kW] | 27 |

*For more technical information, please download and view the relevant documents.

*Technical information may be subject to change!